Development Services

ReSiTec is an industrial company supporting customers with process and product development ranging from laboratory research to industrial scale production. Our staff has strong academic background, but as an industrial business our focus is on industrialization and commercialization rather than academic achievements.

Our main major investments are within pilot- and industrial scale equipment available for external customers and their processes. We do process development, scale-up, and verification, as well as dedicated toll production within powder and slurry processing.

Services offered by ReSiTec:

- Process development

- Product development

- Scale up and piloting

- Toll manufacturing

- Recycling of silicon wafer kerf

- Industrial side stream recycling

Materials processed by ReSiTec:

- Silicon wafer kerf

- Silicon powders wet/moist or dry

- Silicon carbide

- Quartz

- Metallurgical slags

- Graphite

- Coke

- Li-ion battery anode and cathode materials

- NiMH battery waste

- and many more

Areas of expertise:

Chrushing and milling

- Crushing

- Ball and rod milling

- Jet-milling

- Micronization and mineral liberation

Separation

- Separation based on chemistry density or size

- Classification

- Flotation

- Magnetitic

- Electrostatic

- Hydrocyclones

Dewatering and drying

- Dewatering

- Drying of reactive materials

- Filtration

Wet processes

- Process chemistry

- Precipitation and crystallization

- Hydrometallurgy

- Leaching

- Ion adsoption

Analysis

- Powder and slurry characterisation

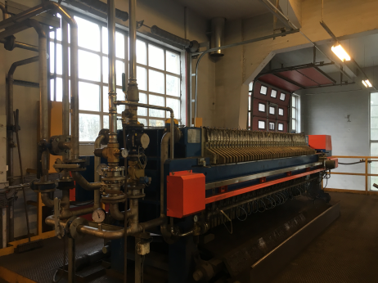

Through production experience and close cooperation with international networks, ReSiTec has gained significant knowledge in powder and slurry handling and treatment. We own two full scale pilot and and production plants, fully fitted with laboratories. A selection of our available pilot equipment can be seen below.

ReSiTec pilots