Projects

Table of Contents

ICARUS 2021-2025

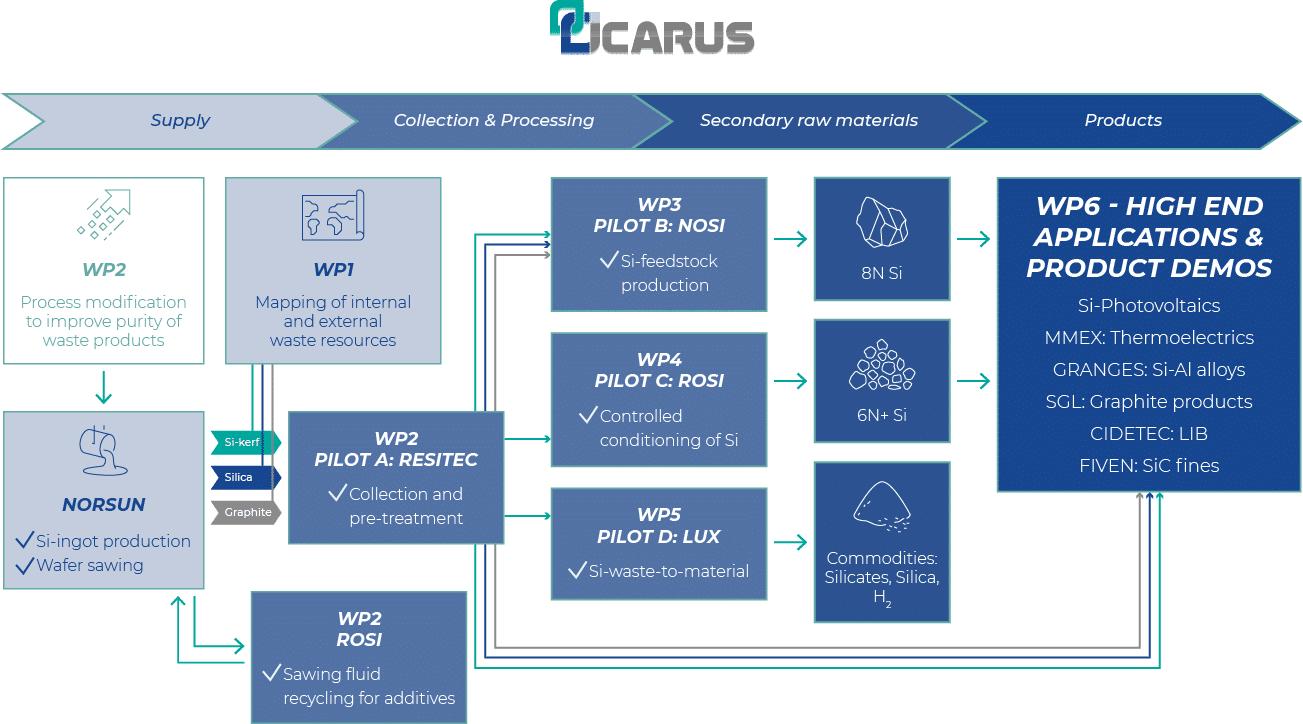

ReSiTec is work package 2 leader in “Innovative eco-efficient processing and refining routes for secondary raw materials from silicon ingot and wafer manufacturing for accelerated utilisation in high-end markets” (ICARUS). A project co-funded by the European Commission Horizon 2020 program.

ReSiTec is responsible for pilot A, which collect, pretreat and process the side streams from the ingot and wafer manufacturing, 1) silicon kerf 2) graphite waste materials 3) silica crucible waste. The processed materials from ReSiTec are tested both directly into various applications as anode material for Lithium-ion batteries (comprises silicon kerf, composites with silicon kerf, and separately graphite waste), thermoelectric modules (silicon kerf), silicon carbide production (silica crucible waste), fine grain graphite (graphite waste) and directly to the other pilots (B, C, D). The consortium is composed of 17 partners: SINTEF, SGL Carbon, ReSiTec, CIDETEC, Granges, FIVEN, ROSI, NOSI, UCY, MMEX, CEA, Lux Chemtech, BIFA, IPG, Benkei, Norsun and Chemcon. The total project budget is 22 M€ and the project started in June 2021 and will run till June 2025.

COBRA 2020-2024

COBRA (CObalt-free Batteries for FutuRe Automotive Applications) is a collaborative research and innovation project on next-generation batteries, co-funded by the European Commission’s Horizon 2020 programme. The project launched in January 2020 and will run until June 2024. COBRA aims to develop a novel Cobalt-free Lithium-ion battery technology that overcomes many of the current shortcomings faced by Electrical Vehicle (EV) batteries via the enhancement of each component in the battery system in a holistic manner. COBRA will use battery chemistry consisting of an LNMO cathode in combination with a composite anode based on nanometre silicon and graphite as active particles. The project will result in a unique battery system that merges several sought after features, including superior energy density, low cost, increased cycles and reduced critical materials. The proposed Li-ion battery technology will be demonstrated at TRL6 (battery pack) and validated on an automotive EV testbed. The involvement of several leading organisations for battery manufacturing ensures easy adaptation to production lines and scale-up to contribute to a higher market adoption while helping to strengthen Europe’s position in the field.

The project has 19 partners and a totalt budget of EUR 11.9 mill. The role of ReSiTec is to develop and provide Silicon powder for use as active material in the anodes.

SELISI 2018-2021

Renewable energies are essential to achieve the objective of reducing the carbon footprint of our modern society. As such a solar panel (photovoltaic / PV Panel), can produce in 2 years the energy that was needed for its production. This carbon footprint can be even lowered by recycling the silicon lost during the different production steps of the PV panels. Indeed, 40% of silicon is lost during the wafering step. The project aimed at recycling and purifying this kerf for its re-use in the Si-based ceramic and photovoltaic industries.

The consortium gathered the expertise of CEA INES specialized in solar energy, ReSiTec, and ECM Greentech, a manufacturer of crystallization furnaces. Erdyn, a French consulting firm specialized in research and innovation, was a subcontractor for CEA and supported the feasibility study and the go-to-market strategy.

In the project, the partners successfully developed a pilot process for production of new solar wafers from recycled silicon kerf.

SELISI was a project partly funded by EIT Raw Materials.

EIT RawMaterials, initiated and funded by the EIT (European Institute of Innovation and Technology), a body of the European Union, is the largest and strongest consortium in the raw materials sector worldwide. Its vision is to develop raw materials into a major strength for Europe. Its mission is to boost competitiveness, growth and attractiveness of the European raw materials sector via radical innovation, new educational approaches and guided entrepreneurship.

CABRISS 2015-2018

ReSiTec was a member and work task leader in the EU project CABRISS. CABRISS was a joint initiative of 16 European companies and research institutes which received approval by the EU’s Horizon 2020 – Research and Innovation framework program.

CABRISS aimed at pioneering a circular economy dedicated to handle the critical situation of recycling the important amount of photovoltaic waste and benefiting also to electronics, metallurgy and glass industries.

CABRISS had the following objectives:

- Developing industrial symbiosis by providing raw materials such as glass or silver pastes as feedstock for other industries (e.g. Glass, electronics or metallurgy).

- Collecting up to 90% of the PV waste throughout Europe compared to the 40% rate in 2013.

- Retrieving up to 90% of the high value raw materials from the PV cells and panels: Silicon, Indium and Silver.

- Manufacturing PV cells and panels from the recycled raw materials achieving lower cost (25% less) and at least the same performances (i.e. cells efficiency yield) as the conventional processes thanks to the implementation of a solar cell processing roadmap, which uses Si waste for the high throughput, cost-effective manufacturing of hybrid Si based solar cell.

- Involving the EU citizens and industry into such a sustainable and financially viable new economy.